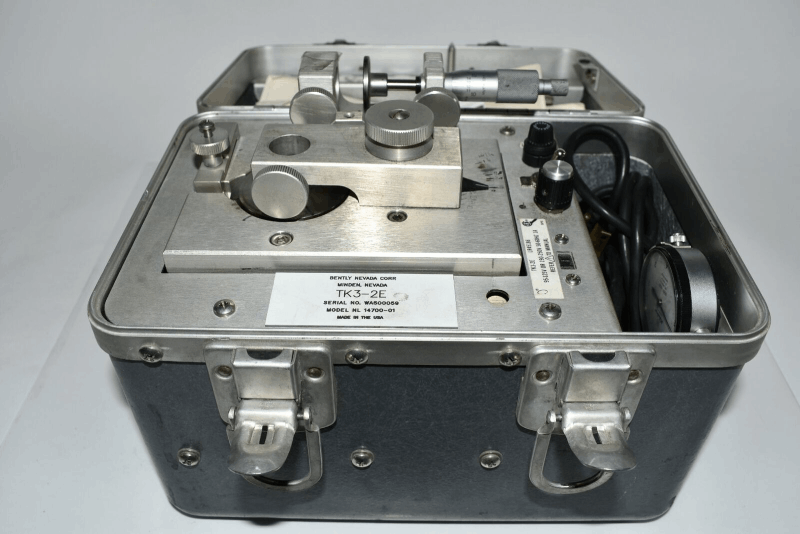

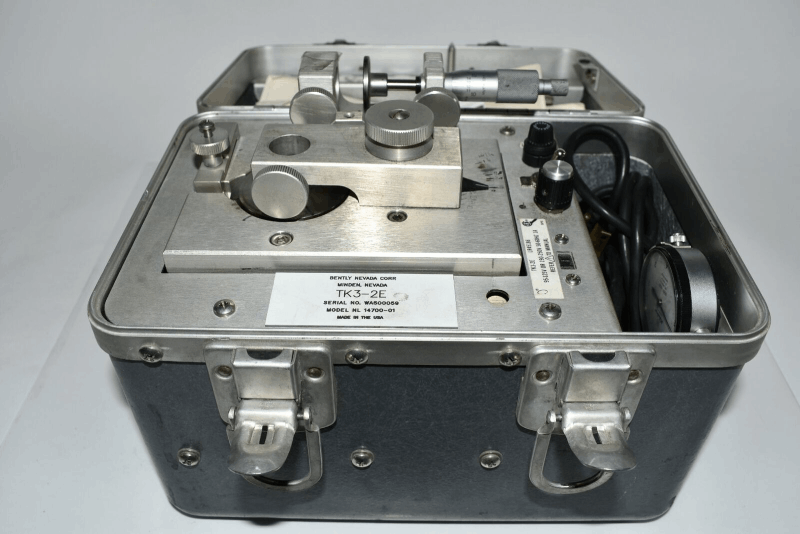

The Bently Nevada TK3-2E is a portable proximity probe test system that simulates shaft vibration and position for calibrating proximity probes. It is used by industrial automation R&D engineers to ensure the accuracy of their proximity probes, which are used to monitor the condition of rotating machinery.

Features

- Simulates shaft vibration and position in the range of 0 to 1000 Hz

- Provides a reference mechanical motion for performing field functional tests of machinery protection systems

- Includes 10 probe adapters to accommodate probes of different diameters

- Spindle micrometer provided to check voltage vs. travel

- LED display shows the current vibration amplitude and frequency

- USB output for connecting to a PC for data logging and analysis

Technical Specifications

- Vibration amplitude range: 0 to 1000 mV

- Vibration frequency range: 0 to 1000 Hz

- Travel range: 0 to 2.5 mm

- Power supply: 115/230 VAC, 50/60 Hz

- Dimensions: 300 x 200 x 100 mm

- Weight: 5 kg

Experience Excellence in Industrial Testing:

The Bently Nevada TK3-2E Proximity Probe Test System embodies precision and reliability. It aligns seamlessly with our dedication to technological advancement and top-tier customer service.

We invite you to connect with us to delve into the world of the TK3-2E Proximity Probe Test System and its transformative impact on industrial automation. Let’s embark on a journey of precision together.

Contact Information:

E-mail: sales6@5gplc.com

Business hours: 24h/7d

Address: No.601, Hongwen Liuli,Siming District, Xiamen,China

More Products

Explore our extensive inventory of Bently Nevada modules. Benefit from advantageous prices, swift shipping, and constant availability. Reach out to us anytime for inquiries.

The Bently Nevada TK3-2E Vibration Monitoring System is an advanced machine protection and condition monitoring system designed to help prevent equipment failures and optimize machine performance. The system is designed to measure vibration, position, and speed of rotating machinery and provide real-time data to operators and maintenance personnel.

The TK3-2E system is composed of a rack-mounted monitoring unit, a sensor interface module, and a range of different types of sensors. The system can be configured to monitor a wide range of rotating equipment, from simple machines such as pumps and fans to complex machinery such as turbines and compressors.

The system uses advanced signal processing algorithms to analyze vibration data and detect potential problems before they become critical. The system can detect a wide range of faults, including bearing wear, misalignment, imbalance, and looseness. The system can also detect changes in the operating conditions of the machine, such as changes in load or speed.

The TK3-2E system is easy to install and configure, with a user-friendly interface that allows operators to set up the system quickly and easily. The system can be configured to provide alarms and alerts when problems are detected, allowing operators to take corrective action before equipment failure occurs.

Overall, the Bently Nevada TK3-2E Vibration Monitoring System is a powerful tool for machine protection and condition monitoring. It provides operators and maintenance personnel with real-time data on the performance of rotating machinery, allowing them to optimize machine performance and prevent equipment failures.

The Bently Nevada TK3-2E Vibration Monitoring System is a high-performance vibration monitoring system designed for use in industrial and commercial applications. Some of the key product features of this system include:

- High Accuracy: The TK3-2E system is highly accurate, providing reliable vibration monitoring data to help detect potential issues before they become critical.

- Easy to Use: The system is designed to be easy to use, with intuitive controls and a user-friendly interface.

- Versatile: The TK3-2E system can be used in a wide range of applications, from monitoring large industrial machinery to smaller commercial equipment.

- Robust: The system is built to withstand harsh industrial environments, and is designed to operate reliably even in extreme conditions.

- Scalable: The TK3-2E system is scalable, allowing users to easily expand the system as their needs grow.

- Advanced Diagnostics: The system includes advanced diagnostic capabilities, allowing users to quickly identify and troubleshoot issues.

- Remote Monitoring: The TK3-2E system includes remote monitoring capabilities, allowing users to monitor equipment from a distance and receive alerts when issues arise.

Overall, the Bently Nevada TK3-2E Vibration Monitoring System is a powerful and versatile tool for monitoring vibration in industrial and commercial applications, providing users with the data they need to keep their equipment running smoothly and efficiently.

Q: What is the Bently Nevada TK3-2E Vibration Monitoring System?

A: The Bently Nevada TK3-2E Vibration Monitoring System is a machine monitoring system designed to provide continuous vibration monitoring and analysis for rotating machinery. It is capable of detecting potential machinery problems and alerting operators before they become critical failures.

Q: What types of machinery can the TK3-2E monitor?

A: The TK3-2E can monitor a wide range of rotating machinery, including pumps, compressors, turbines, motors, and generators.

Q: What are the key features of the TK3-2E?

A: The TK3-2E features advanced vibration analysis capabilities, including spectrum analysis and waveform analysis. It also includes a user-friendly interface and customizable alarm settings.

Q: How does the TK3-2E work?

A: The TK3-2E uses accelerometers to measure vibration levels on the machinery being monitored. This data is then analyzed by the system to detect potential problems and alert operators.

Q: What are the benefits of using the TK3-2E?

A: The TK3-2E can help reduce downtime and maintenance costs by detecting potential machinery problems before they become critical failures. It can also improve overall equipment reliability and extend the life of machinery.

Q: What is spectrum analysis?

A: Spectrum analysis is a technique used in vibration analysis to break down the vibration signal into its individual frequency components. This allows operators to identify the specific frequencies that are causing the vibration and determine the root cause of the problem.

Q: What is waveform analysis?

A: Waveform analysis is a technique used in vibration analysis to analyze the shape and characteristics of the vibration signal. This can help operators identify specific types of vibration, such as bearing faults or misalignment.

Q: How customizable are the alarm settings on the TK3-2E?

A: The TK3-2E includes a variety of customizable alarm settings, including alarm thresholds, alarm delays, and alarm priority levels. This allows operators to tailor the system to meet their specific needs and requirements.

Q: What types of accelerometers can be used with the TK3-2E?

A: The TK3-2E is compatible with a wide range of accelerometers, including both piezoelectric and piezoresistive types.

Q: Is the TK3-2E suitable for use in hazardous environments?

A: Yes, the TK3-2E is designed for use in hazardous environments and is certified for use in Class I, Division 2, Groups A, B, C, and D environments.

6G Controls - Leading Supplier of New & Original PLC 、DCS Parts and Automation Controller

6G Controls - Leading Supplier of New & Original PLC 、DCS Parts and Automation Controller

-jpg.webp?w=300&resize=300,300&ssl=1)

-1.jpeg?w=300&resize=300,300&ssl=1)