Overview

- The Bently Nevada 288055-01 TDI is a standard TDI module that provides a high-speed, bi-directional interface between the 3500/22 Condition Monitoring System and GE’s System 1* machinery management software.

- The TDI can be used to collect and transmit transient data from a variety of sources, including vibration sensors, accelerometers, and proximity probes.

- The TDI also supports a variety of triggering options, allowing users to collect data based on specific events, such as bearing failures or motor trips.

Features

- High-speed, bi-directional interface

- Supports a variety of triggering options

- Collects and transmits transient data from a variety of sources

- Rugged and reliable design

Technical Specifications

- Data transfer rate: 100 Mbps

- Transient data storage: 16 MB

- Triggering options: Time, event, and threshold

- Input channels: 16

- Output channels: 2

- Dimensions: 9.5 x 6.7 x 2.2 inches

- Weight: 1.3 pounds

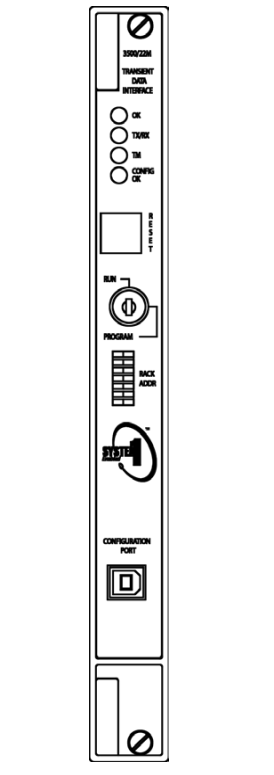

3500/22M Transient Data Interface (TDI)

Description:

The 3500 Transient Data Interface (TDI) serves as the interface between the 3500 monitoring system and GE’s System 1* machinery management software. It combines the capabilities of a 3500/20 Rack Interface Module (RIM) with the data collection functionality of a communication processor like TDXnet.

Operation:

- The TDI operates in the RIM slot of a 3500 rack, working alongside M series monitors (e.g., 3500/40M, 3500/42M, etc.). It continuously collects steady-state and transient waveform data and sends this data via an Ethernet link to the host software. (Refer to the Compatibility section for details.)

- Static data capture is a standard feature of the TDI. However, using an optional Channel Enabling Disk enables the TDI to capture dynamic or transient data.

- The TDI improves upon several aspects compared to previous communication processors and incorporates the Communication Processor function within the 3500 rack.

Effect on Monitoring:

- Although the TDI provides certain functions common to the entire rack, it does not form a part of the critical monitoring path and does not affect the proper, normal operation of the overall monitor system.

- Every 3500 rack requires one TDI or RIM, and it always occupies Slot 1, which is positioned next to the power supplies.

Triple Modular Redundant (TMR) Applications:

- For TMR applications, the 3500 System necessitates a TMR version of the TDI.

- In addition to standard TDI functions, the TMR TDI also performs “monitor channel comparison.” The 3500 TMR configuration executes monitor voting using the setup specified in the monitor options.

- Using this method, the TMR TDI continually compares the outputs from three (3) redundant monitors. If the TDI detects that the information from one of those monitors is no longer equivalent (within a configured percent) to that of the other two monitors, it will flag the monitor as being in error and place an event in the System Event List.

For more parameters, please read the PDF of our 3500/22M Transient Data Interface: 3500-22-01-01-CN

Maybe you are interested in the same 3500/22 series:

- Bently Nevada 3500/22 146031-01

- Bently Nevada 138607-01 3500/22M

MORE Bently Nevada Products:

- BENTLY NEVADA 3500/05-01-01-00-00-00

- BENTLY NEVADA 9200-03-05-10-00

- BENTLY NEVADA 136180-01

- BENTLY NEVADA 176449-03

- BENTLY NEVADA 9200-01-05-10-00

- BENTLY NEVADA TK3-2E

- BENTLY NEVADA 330106-05-30-05-02-00

- BENTLY NEVADA 172323-01

- BENTLY NEVADA 330105-02-12-10-02-00

- BENTLY NEVADA 176449-02

- BENTLY NEVADA 176449-04

- BENTLY NEVADA 125712-01

- BENTLY NEVADA 125744-02

- BENTLY NEVADA 138607-01

- BENTLY NEVADA 135785-01

- BENTLY NEVADA 330103-00-06-10-02-00

- BENTLY NEVADA 330180-50-05

- BENTLY NEVADA 330780-91-00

- BENTLY NEVADA 330104-00-04-10-02-CN

- BENTLY NEVADA 330104-00-08-10-02-00

- BENTLY NEVADA 330103-00-04-10-02-00

- BENTLY NEVADA 330103-00-12-10-02-CN

- BENTLY NEVADA 330106-05-30-10-02-CN

- BENTLY NEVADA 167669-01

- BENTLY NEVADA 330103-00-06-05-02-00

- BENTLY NEVADA 330103-00-09-05-02-00

- BENTLY NEVADA 288055-01

-768x1024.jpg)

-150x150.jpg)

-150x150.jpg)

-150x150.jpg)

-150x150.jpg)

-jpg.webp?w=300&resize=300,300&ssl=1)

.jpg?w=300&resize=300,300&ssl=1)